Culvert Liner Systems

We bring you the best possible products for your project.

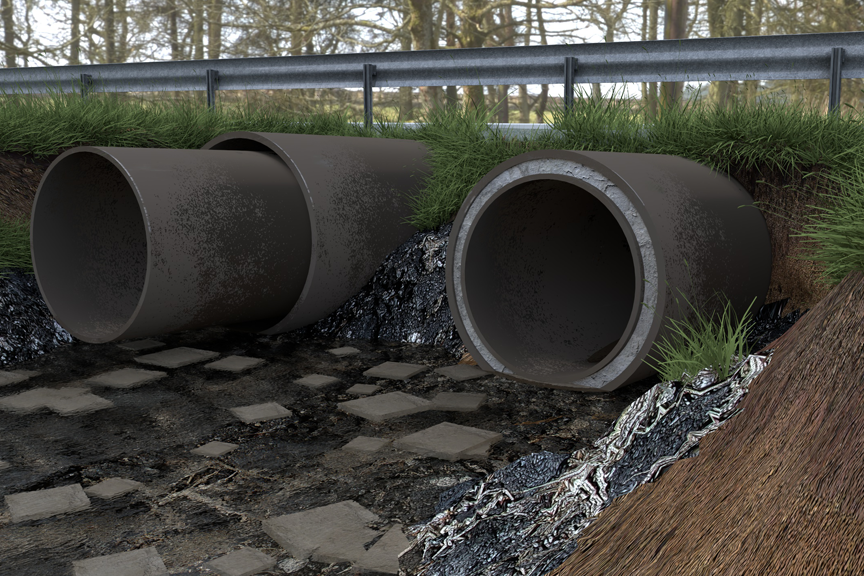

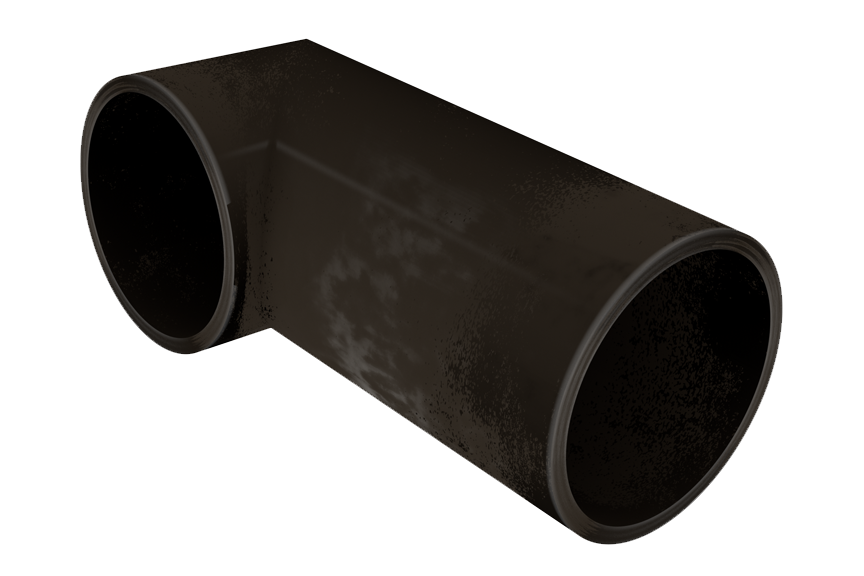

Round Liners are designed to any dimension from 30” and above, with wall thicknesses from ½” up to 2.00”. These are typically furnished in 20’ long sections. However, shorter and longer pieces are available.

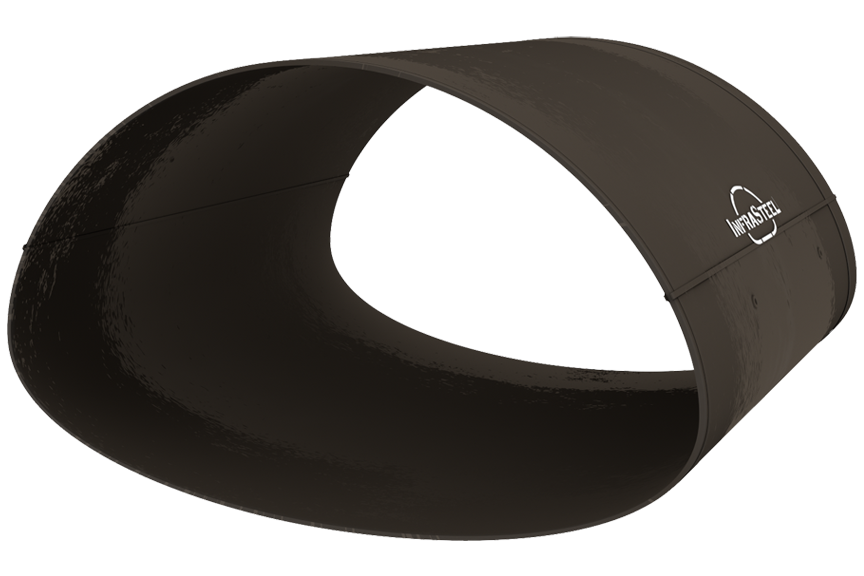

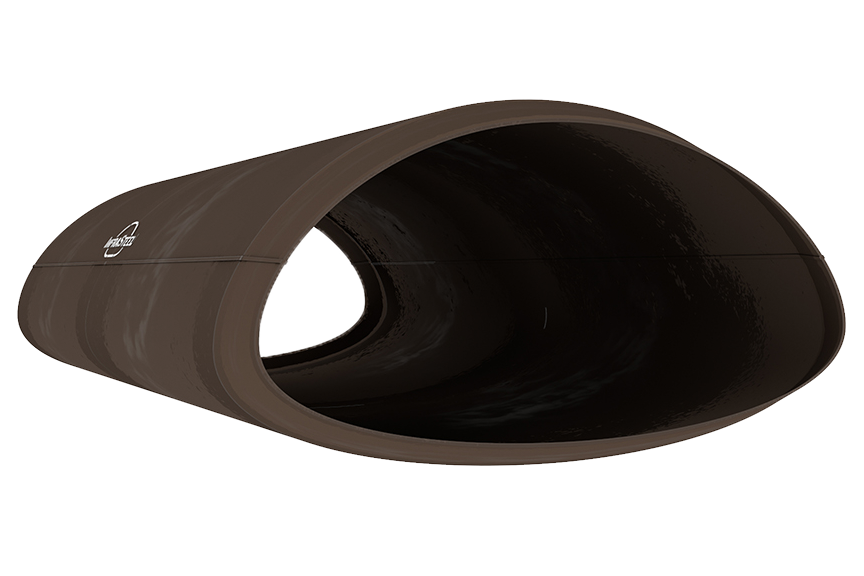

Arched & Elliptical Liners are designed to match the radii of the existing structure in order to maximize the hydraulic area of flow. We manufacture these shapes with spans up to 20’ wide in thicknesses from ½” to 2.00”. Arch & Elliptical Liners are most commonly shipped in 8’-10’ lengths due to shipping and job site handling.

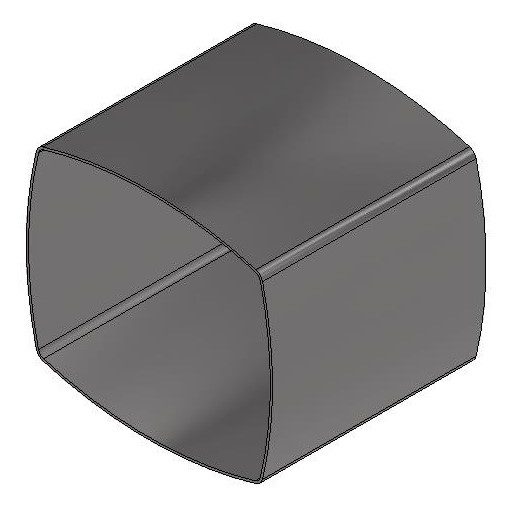

Our box culvert design maximizes the liner’s hydraulic area of flow and is engineered to meet the load bearing requirements of the project site. Whether the overhead traffic is a railway or roadway, our MAXBOXX liner will handle the load. The liner thickness is determined by our structural engineers, and additional steel is added to the wall thickness for each year of design life required by the project owner.

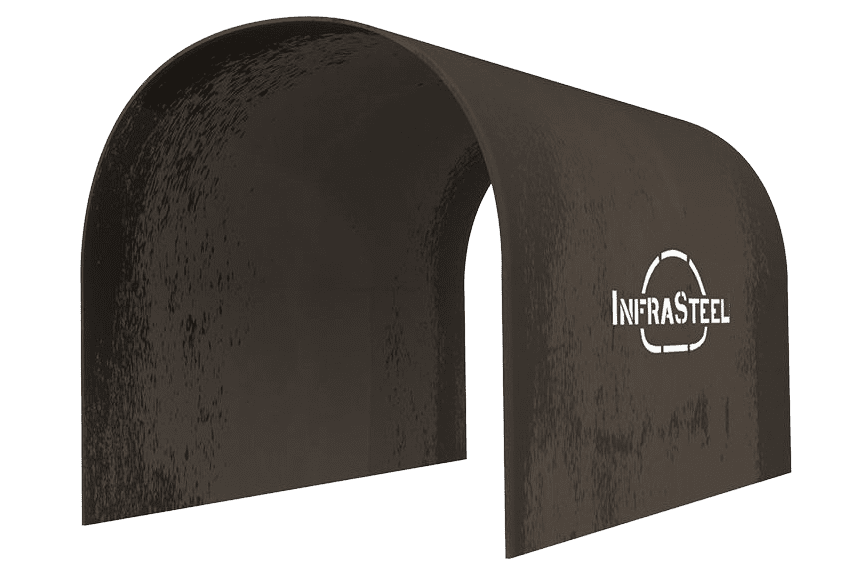

Top Arch Liner designs were developed primarily to rehabilitate old masonry arch structures. These designs have a more exaggerated arched top with vertical sidewalls and are manufactured in wall thicknesses up to 2.00”. They are often manufactured as components of composite designs.

When environmental impact and aquatic organism passage are a concern, Bottomless Top Arch designs are available. In this application, the liner is welded to knee walls that are built inside of the failing structure. This often allows for a taller liner rise and for the original natural bottom to be maintained.

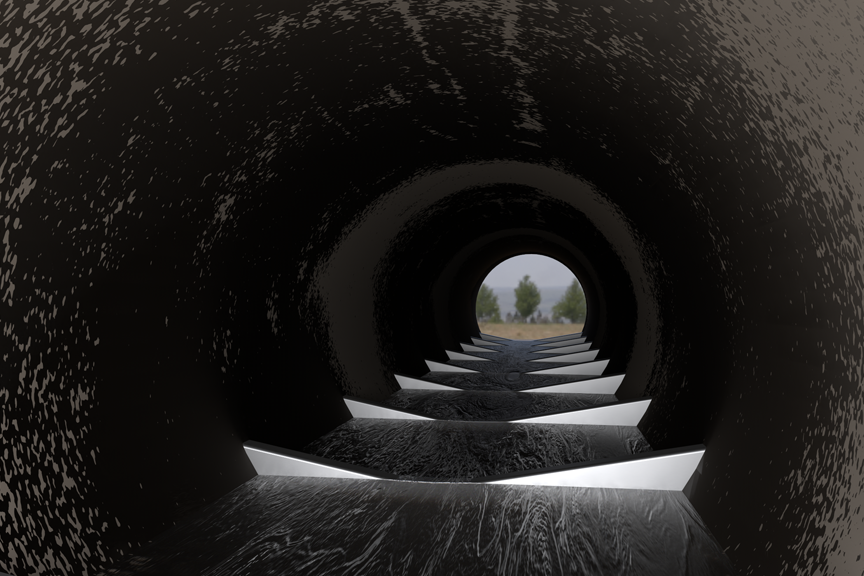

InfraSteel’s FLOW BELL is an invaluable component of culvert design. It’s a flared beveled inlet attachment, designed to improve the flow characteristics of the rehabilitated structure. Each FLOW BELL is manufactured for the inlet of the specific site, and it may be welded to the liner or both the liner and headwall. A typical design is ½” per diameter foot in width, with a beveled edge. Other widths and angles can be manufactured, including side and slope-tapered entrances. These features decrease the head loss as the flow enters the culvert. Flow Bells are expected to be used widely on future designs; due to increasingly common, rising headwater, limitations.

Modular Headwalls and Wing Walls are manufactured to accommodate the dimensions and requirements of the project site, and often incorporate FLOW BELLs, Toe Plates for cutoff walls, and steel Aprons. Headed Anchor Studs can also be added to the back of the InfraSteel Headwall, in order to tie into existing structures with concrete.

Conical Lead Pieces are culvert products manufactured to facilitate the slip lining process. The pointed cone shaped sections are welded onto the 1st section of liner, that is to be inserted into the existing structure. These are used to prevent the lead end of the liner from snagging or hanging up on bolts and deformations in the existing culvert.

Fish Baffles are designed to be welded to the bottom of the liner once it is installed. They can also be manufactured in a variety of configurations to satisfy the environmental requirements of the project owner.

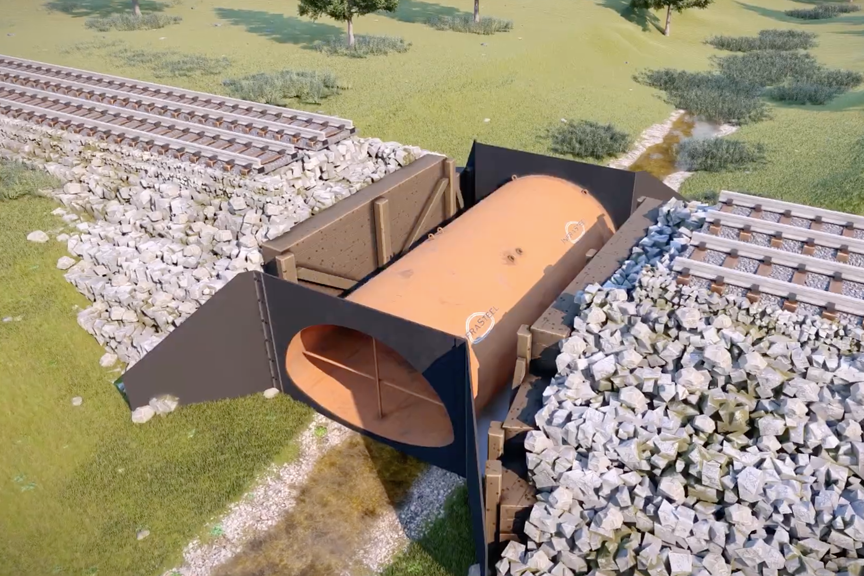

Bridge Kits are designed primarily to replace timber bridges. These culvert products are assembled with InfraSteel product features, placed in position, and then covered with concrete. This ensures minimum railway or road traffic downtime. The barrels of the kits are designed to meet the hydraulic and load bearing requirements of the site. Once completed, the rehabilitated site is maintenance free.