Project Description

The Project

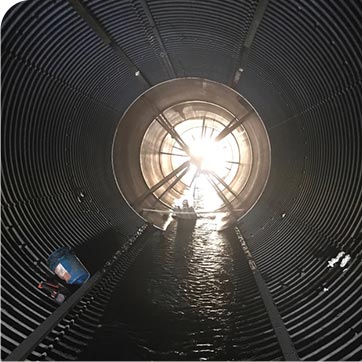

InfraSteel was used by Midwest Mole of Greenfield, IN to slip-line a 245’ long, 144” diameter failing Corrugated Metal Pipe culvert under US 31 in Miami County Indiana. US 31 is a heavily traveled north south thoroughfare in Indiana, so the Indiana Department of transportation determined that slip- lining was the best option for repairing the failing structure.

The Challenge

Midwest Mole had to remove approximately 2’ of silt from the bottom of the existing structure in order to determine what size would fit inside of the host pipe structure. Once the silt was removed a survey of the line was completed for both elevations, and the alignment of the existing pipe.

A mandrel built to the OD of the proposed liner was assembled and pulled through the existing pipe prior to final dimensions of the liner being released for fabrication to verify that no issues would arise once the lining commenced. A round liner with an ID dimension of 135” was determined to be the best size for this structure. D. H. Charles Engineering’s Cardiff California office did the load bearing calculations to determine the wall thickness that would meet HS-20 load bearing requirements, considering the worst case with the tire directly over the top of the culvert for vehicle weight with 5’ of cover, and on 6’ of cover for soil weight. A sacrificial loss of .280 inches was added to provide the 70-year life expectancy, based on the culvert being located in an immersed zone with corrosive water. A wall thickness of ¾” was determined to be the appropriate wall thickness for this particular project.

This project coincided with other paving work being done nearby on US 31 that would have caused additional delays or complications in getting both projects completed in a timely manner if road closures or detours would have been required for this work. Road closure and detours are one of the greatest costs of culvert failure. Because once failure has occurred, and the road has collapsed there is no option for emergency vehicles, commercial vehicles and the traveling public except to detour around the failure.

The Solution

Midwest Mole unloaded the InfraSteel liner directly from the delivery trucks to the construction pit. Steel runners were installed onto the bottom of the existing CMP to allow the steel liner to ride on top of, as it was being pushed into place. Also, grease was applied to the runners to help reduce friction between the InfraSteel liner and the steel runners, which is the best way to insure a smooth insertion. InfraSteel liner can be pushed into place without using steel runners, however using bar stock, channel iron or angle iron as a track system definitely facilitates the insertion process for most applications.

A Boring machine track was set up in the ditch line of the construction area, and the liner sections were placed on the track. The push pack of the boring machine was used to slip line the sections into place inside of the failing structure. The insertion process of the 245’ of InfraSteel liner took three days. Once the pipe was in place it was welded from the ID in approximately 1 week. Midwest Mole used a cellular grout to fill the annular space between the old CMP and the new InfraSteel liner.