The Historical Role of Drainage Structures

Drainage structures have been used for thousands of years to keep people dry and improve living standards. They are built to manage the collection and conveyance of stormwater. They protect us from rain and flood damage, allow us to have running water in our homes, and help us travel over rivers and streams. Drainage structures play an essential role in the civilized world, giving us comfortable homes and transportation.

It is fascinating that ancient roads with stone drainage structures built by the Romans 2,000 years ago have endured while our modern infrastructure crumbles. Unfortunately, the importance of drainage structures in the conversation of modern infrastructure often takes a back seat to more glamorous infrastructure topics.

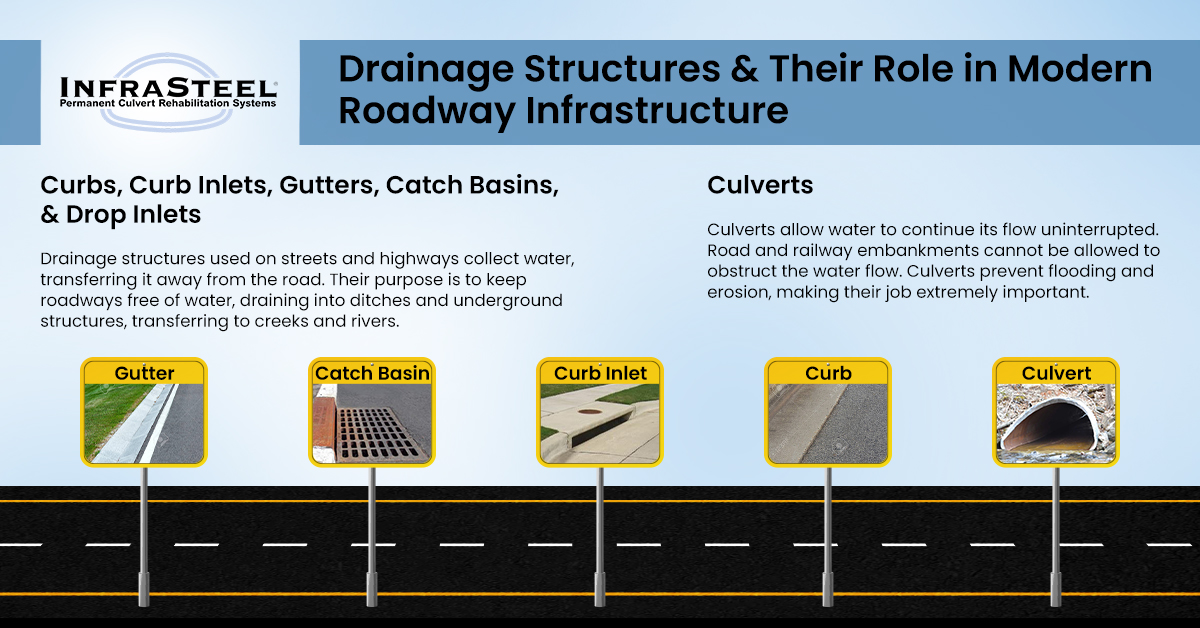

Drainage Structures For Streets & Highways

Drainage structures used on streets and highways collect water, transferring it away from the road. These often consist of curbs and curb inlets, gutters, culverts, catch basins and drop inlets. Their purpose is to keep roadways free of water, draining into ditches and underground structures, transferring to creeks and rivers.

In urban areas, the runoff may enter into a stormwater pipe underground that is effectively contained before it is deposited back into the environment. An example of this is New York City’s complex underground drainage system. The street drainage structures allow water to collect in Stormwater Conveyance Structures, keeping the streets free and clear of standing water. Just think how at the turn of the 20th Century, the streets were a mess due to the bi-product of horse carriages combined with poor surface drainage.

When roads are built, the natural drainage of the right-of-way area is changed. Areas of natural drainage must be bridged with structures that allow the water to pass under the road. Only in extremely rural areas and areas of low rainfall should the water be allowed to cross over the road. During road construction, culverts and bridges are installed to allow the water to flow beneath the road to protect the road and enable travelers safe passage.

The Size Of Drainage Structures

When it comes to drainage structures, size matters. If a drainage structure is undersized, it will fail to transfer water at peak drainage times adequately. However, other factors also affect flow rates. Think of how an inlet improvement, like a funnel, can increase flow by loading the smaller barrel with liquid faster. Likewise, the roughness of the drainage structure (Manning’s Coefficient) in contact with the water flow also plays a part in flow rates; the rougher the surface, the slower the flow rate. These considerations have to do with the hydraulics of the structure, and they should be incorporated with environmental studies and the science of hydrology. It is often the work of a specialist in hydrology and hydraulics who determines the best drainage structure design.

Drainage Structures: Materials, Shape, and Size

Corrugated metal pipe, concrete pipe, and steel pipe are the most commonly used storm drainage pipes. They come in various shapes and sizes to accommodate the needs of particular sites. As with any building material, those used to convey stormwater should be economical to build, hydraulically adequate, structurally durable, and easy to maintain. The designer must also factor in the load-bearing capacity of the chosen product by evaluating the depth of bury, desired load rating, and expected life expectancy.

The shape and size of the culvert must also be considered when doing the structural analysis of the particular site. It is crucial to have a thorough understanding of these factors so that the drainage structure will perform during peak water events and support the surrounding soil and traveling surface.

Maintaining and Inspecting Drainage Structures

Drainage structures require little maintenance; however, because culverts are an integral part of road, highway, and railway infrastructure, active culvert inspection is needed to ensure they are performing as designed. Passages should be clear of debris that restricts flow and cause water to back up. Also, the inspection of the structural integrity of culverts is vital to head off any possible failure that could cause a road or railway to collapse.

A dip in a road or guardrail at a culvert location indicates the culvert below is failing. This failure occurs as the structural integrity of the culvert deteriorates over time due to scouring, which appears at the invert. The abrasive nature of sand, gravel, and dirt mixed with flowing waterworks deteriorates the bottom of the existing culvert structure. As the invert deteriorates, the culvert loses structural integrity. The original designer’s structural concept has been changed by the wear of the abrasion over the life expectancy of the culvert design.

How To Prevent Culvert Failure

When culvert failure occurs, there becomes a possibility of road or railway failure. Often these failures are reported by the news as “sinkholes,” and they may result in accidents and deaths. These failures often cause detours that impede emergency vehicle response and affect commerce and the lives of the traveling public.

To prevent the possibility of culvert failure, professionals must determine a solution for the repair and rehabilitation of the culvert site. Often the replacement of the culvert is not possible due to the depth of bury, high traffic count, length of detours, or other significant factors. When replacement is not an option, slip-ling the existing culvert with a new pipe should be considered. Slip lining is when a new pipe is inserted inside the current failing pipe, and the annular space is grouted. The new pipe not only assumes the role of displacing the water but also retaining the structural integrity of the original structure. Failing culverts can be slip-lined with a variety of rigid pipe products. They can also be repaired with spray-on liners and cured-in-place liners. Ultimately the best possible solution for the rehabilitation of the existing culvert structure needs to be determined.

Culvert Repair Practices That Work

There are many factors to consider when choosing the best method of repairing a culvert. The cost, ease of installation, structural and flow rate characteristics are a few examples. At Precision Pipe and Products, we have developed a user-friendly design matrix to help decision-makers determine the best repair method for their site. The Culvert Rehab Products Evaluation Spreadsheet at www.INFRASTEEL.com can evaluate any culvert rehab method and allow the user to rank the most important considerations. This is a great tool to use when trying to decide on culvert rehabilitation methods and products.

At Precision Pipe and Products, we developed our InfraSteel liner to satisfy market demand for a structural design with maximized flow characteristics and calculated design life. We engineer the design features required by the project owners by manufacturing site-specific liners that meet the needs of project owners. For more content relating to culverts and stormwater infrastructure, please visit us at www.INFRASTEEL.com or follow us on Facebook/Instagram/Twitter @InfraSteelUSA.

Leave A Reply